Company Overview

| Company Name | Nibishi Shoyu Co., Ltd. |

|---|---|

| President and Chief Executive Officer | Shigeo Suematsu |

| Date of establishment | October 20, 1919 |

| Capital Stock | JPY 90,000,000 |

| Business Description | Manufacture and sale of shoyu (soy sauce), miso, mentsuyu, processed condiments (for soups), brewed vinegar, sauces, and other food products |

| Headquarters/Factory | 3-2-1, Ekihigashi, Koga City, Fukuoka Prefecture, 811-3102, Japan Telephone: +81-92-943-2231, Facsimile: +81-92-943-3050 |

Company Overview

1919: The company was founded in its present location by Seiichi Suematsu, its first president, and 107 other shareholders, with a capital of 1 million JPY under the name of Nihon Chomiryo Jozo Co., Ltd.

1959: Invention and unveiling of the "Unmanned koji (malted rice and barley) making machine" which contributed to the technological development of the industry.

1965: Changed the company name to the current "Nibishi Shoyu Co., Ltd."

1970: With the integration of the Yanagawa factory into the Koga factory, and the improvement and expansion of the factory facilities, we were striving to improve our technology and control the quality of our products under the motto "Brewed products are alive."

1976: The sales department was reorganized and an independent sales company was set up. The sales network was expanded to ensure supply and service in all regions.

2016: Newly established a bottling factory, our fifth factory, and a product warehouse.

At our bottling plant, we introduced machines that could handle a variety of containers, including PET bottles for soups and dashi (Japanese Bonito broth) and bottle products to preserve freshness that has enabled us to improve our productivity as well as expand our product range.

Our fifth plant has made it possible to produce pot soups, ramen, and champon soup more hygienically, as well as create an environment that will allow us to experiment with new areas in the future.

| 1919 | Established Nippon Chomiryo Jozo Co., Ltd. |

|---|---|

| 1920 | Built the Koga factory and started soy sauce production |

| 1921 | Started miso and vinegar production |

| 1923 | Established a platform exclusively for Nibishi at the Koga station on the Japan National Railways Kagoshima line |

| 1925 | Operations for sauces begin |

| 1948 | Took over Nippon Shokuhin Co., Ltd. and launched the Yanagawa factory |

| 1949 | Head office moved to Sumiyoshi Jinja-mae, Fukuoka |

| 1955 | Koga factory designated as an excellent factory for heat management |

| 1959 | Disclosed our company’s unmanned koji production technology for installing our patented koji production room to soy sauce traders across the country |

| 1960 | Established Nibishi Unso Co., Ltd. |

| 1965 | Changed the company name to "Nibishi Shoyu Co., Ltd." |

| 1970 | Integrated Yanagawa factory’s production activities into Koga factory |

| 1972 | Added pressing equipment, introduced a new small bottling line, implemented soy sauce quality labeling and JAS standards |

| 1973 | Permanently installed koji making equipment and warm fermentation tanks |

| 1975 | Completed the waste water treatment equipment and soy sauce koji making equipment |

| 1980 | Established Nibishi Shokuhin Kabushiki-Kaisha |

| 1992 | Introduced the new 1.8 L bottling line |

| 1994 | Opened the new Koga factory office and dismantled the concrete chimney installed in 1957 |

| 1995 | Completed the construction of the new administration building and the transport and distribution platform |

| 1996 | Relocated and newly set up the vinegar and sauce factory |

| 1999 | Newly set up the pasteurization and filtration factory, marking the 80th anniversary of the company |

| 2003 | Relocated the sales headquarters to the Koga factory |

| 2004 | Head office registration changed from Fukuoka City to Koga City |

| 2008 | Renewal of the soybean steaming container Integrated Nibishi Shokuhin Co., Ltd. into Nibishi Shoyu Co., Ltd. |

| 2014 | Changed the boiler fuel from heavy oil to city gas (Reduction: CO2 615 t-CO2/year) |

| 2015 | Relocated the mixing factory |

| 2016 | Newly built the fifth factory, bottling factory, and product warehouse |

| 2019 | Celebrated our 100th anniversary Acquired certification of the international standard for food safety "FSSC22000" |

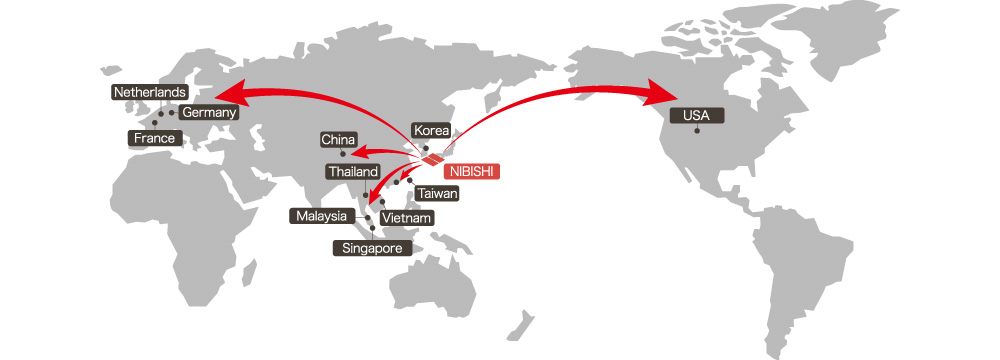

Export Achievements

Delivering the taste of Fukuoka, Japan to the world

Amidst the worldwide boom of Japanese food, we mainly export soy sauce and ramen soup as seasonings from Kyushu that appeal to overseas customers as well.

[Main export regions]

Korea, China, Taiwan, Thailand, Vietnam, Singapore, Malaysia, Germany, France, Netherlands, USA

Food Safety

Acquisition of the international food safety standard

“FSSC22000”

We have acquired the FSSC22000 certification which is an international standard for food safety management systems. With the acquisition of the FSSC22000 certification, we are committed to improving food safety in order to deliver even safer and more reliable products to our customers.

Scope of certification: Processing of soy sauce, soups, vinegar, sauces, tares, and dairy products (excluding miso)

*FSSC22000 is one of the food safety certification schemes approved by GFSI (Global Food Safety Initiative). It is based on the international standard ISO 22000 for food safety management systems with the addition of the prerequisite program ISO/TS22002-1 for food safety and the additional requirements of FSSC22000.